Mooney viscosity—PC type distribute|mooney mdr viscosity : private label Mooney viscosity measures the stiffness of the uncured compounds, otherwise known as the compound’s viscosity. The appropriate standards associated with this test are IS0 289, ASTM D 1646, and DIN 53523-3. The units of measurement are known as Mooney units. Resultado da Lucky Jet for real money in the casino 1Win with a convenient withdrawal 2023. Lucky Jet is a popular crash game, presented in the catalog of the 1Win casino. .

{plog:ftitle_list}

Resultado da Most Popular. Videos 2. Backdrops 53. Posters 56. A complex drama about power politics in the world of New York high finance. Shrewd, savvy U.S. .

Mooney viscosity measures the stiffness of the uncured compounds, otherwise known as the compound’s viscosity. The appropriate standards associated with this test are IS0 289, ASTM D 1646, and DIN 53523-3. The units of measurement are known as Mooney units.Materials. Robert Flitney, in Seals and Sealing Handbook (Sixth Edition), 2014. .A Mooney viscometer is an instrument used for measuring the Mooney viscosity of rubbers. Invented by Melvin Mooney, it contains a rotating spindle and heated dies, the substance encloses and overflows the spindle and the mooney viscosity is calculated from the torque on the spindle.

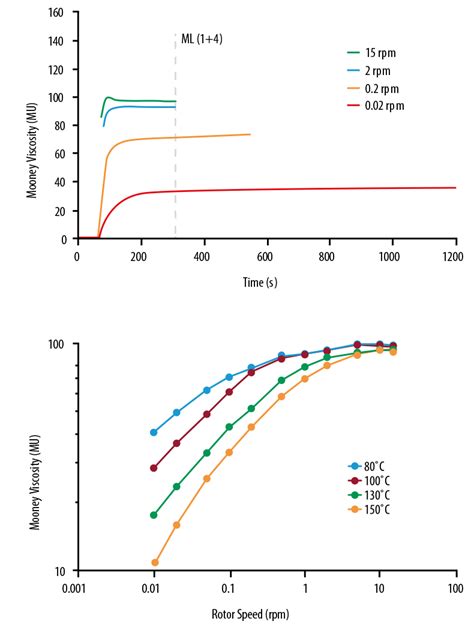

Mooney viscosity measurements have been found helpful in estimating the processing characteristics of rubbers. They must be supplemented by other types of tests, however, .Mooney Viscometer Model: UM-2050 Test Reports: Test Report of Mooney Viscosity Test Report of Mooney Scorch Standard Functions: Viscosity Test a) Mooney initial (MI) b) Minimum viscosity (ML) c) Maximum viscosity (MF) d) Testing temperature curve Scorch Test a) Scorch time at T5 and T35 for large rotor ; or at T3 and T18 forMooney viscometer The sample cavity of the Mooney vis-cometer is shown in Fig. 1. The rotor is embedded in a sample and the torque required to move the rotor at 2 rpm is measured. A typical Mooney viscosity measurement is the ML1+42. This test uses a 1 minute preheat with the motor off and then 4 minutes with the motor on at 2 rpm.

The Mooney viscosity of the sample set was measured by the standard method and the values were in the range 65–95 units. The samples were divided in two subsets, one for calibration, containing 70 samples, and the other for external validation, containing the remaining 30 samples. The Mooney viscosity average values and their standard .LIQUID-LIQUID EMULSIONS 213 16.0 14.0 • SYS1ElA 2 • SYS1ElA 8 12.0 • SYSTEflot 9 10.0 I~Is, 8.0 6.0 4.0 2.0 0.0 1.0 2.0 3.0 4.0 5.0 In7J r FIGURE 4 Typical In n.t»versus In fl. plots. typical plots. The data of In TJr/ ep versus In TJr are linear; the slope (K2) and the intercept (K ,) vary from system to system. Table 1 summarizes the values of K. and K2 for the various .

Different rubber compounds may exhibit varying Mooney Viscosity values based on factors such as the type of rubber, the presence of additives, and the degree of vulcanization. The test is particularly useful for comparing different formulations and optimizing rubber processing parameters to achieve desired properties and performance in the . From 0 to 36 h, the Mooney viscosity of NR-Salt increased, and it reduced slightly after 36 h. From 0 to 24 h, the Mooney viscosity of NR-Acid increased, and it is decreased slightly after 36 h. Hardening occurs when NR is stored, causing the increase in Mooney viscosity, but on prolonged storage NR molecular structure will rupture. Therefore .Mooney viscosity measurements have been found helpful in estimating the processing characteristics of rubbers. They must be supplemented by other types of tests, however, before a comprehensive measure of processibility can be obtained. References. 1.

mooney viscosity test

5 Table 2: Comparison of NORDEL™ EPDM grades in peroxide-cure test recipe (continued)(1, 2, 3) Property NORDEL™ EPDM grades 4725P 4760P 4770P 4785HM 4820P 5565 Mooney viscosity, ML 1 + 4, 100°C 31 65 72 84 22 67influence of feed compositions on rubber Mooney viscosity† Ge He, ab Tao Luo,*a Yagu Dang,a Li Zhou,a Yiyang Daia and Xu Ji*a Mooney viscosity is an essential parameter in quality control during the production of nitrile-butadiene rubber (NBR) by emulsion polymerization. A process model that could help understand the influence ofHNBR-AT possesses a Mooney viscosity more than 20 MU less than HNBR-4367 and close to 30 MU less than HNBR-3907. It is quite obvious that blending in HNBR-AT into these two polymers will provide a significant decrease in their Mooney viscosity values. The raw polymer Mooney data agrees well with the published midpoint data provided in the appendix. The final torque during processing and the Mooney viscosity of rubber increased with molecular weight due to tie chain entanglements, as later confirmed by a dynamic mechanical analyzer. . (MW) and molecular weight distribution (MWD) of NR from different age and clone Hevea trees. Songklanakarin J Sci Technol 2005; 27(2): 337–342.

5. The maximum test time: Mooney: 10min; Scorch: 120min (modification time during testing) 6. Mooney value of measuring range: 0 to 200 7. Mooney value resolution: 0.1 Mooney value 8. Mooney value measurement accuracy: ± 0.5 Mooney value 9. Calibrate accuracy: 100±0.5 Mooney value 10. Rotor speed: 2 ± 0.02r/min 11.Mooney Viscosity The Mooney Viscosity test is the most popular test method for characterizing polymers and uncured rubber materials. As defined by international standards, the sample material is preheated for a defined period in a closed die cavity, then 48. sheared by the embedded rotor at a constant rate. The Mooney Viscosity is recorded

ISO 289-1:2015 specifies a method using a shearing-disc viscometer for measuring the Mooney viscosity of uncompounded or compounded rubbers. General information. Status : Published. Publication date : 2015-09. Stage: International Standard confirmed Edition : 4. Number of pages : 17. Technical Committee :

2. Test data: contains the Mooney viscosity, scorch various data; 3. Test curve: Mooney viscosity curve, Mooney scorch curve, temperature curve of the upper and lower mold 4. Modify the time during testing 5. The test data can be saved . Traditional data-driven empirical models for online prediction of the Mooney viscosity have not utilized the information hidden in lots of unlabeled data (e.g., process input variables during each mixing batch). A simple semi-supervised nonlinear soft sensor method for the Mooney viscosity prediction is developed. ISO 289 Parts 1 and 2 also describes the determination of Mooney viscosity and pre-vulcanization characteristics. In addition to a few insignificant differences there are major technical differences between ISO 289 and this test method in that ISO 289 does not provide for sample preparation on a mill, while this test method allows milling .

Mooney Viscosity. This test is the most commonly used test method for characterizing uncured rubber materials and polymers. The sample material is heated for a predetermined period of time, then sheared by an embedded rotor at a constant rate. We then record the Mooney Viscosity and automatically calculate data at defined times and viscosity .level and wide distribution range. Low Mooney viscosity rubber easy to adhere to the roll, its molecular weight is low and narrow distribution range. Scorch time is a physical quantity to mea- . Ltd. : xk-160 type smelting machine; Alpha corpo-ration: Mooney viscometer MV2000. 1.4 Sample preparation The mixing rubber was prepared by .

Mooney viscosity is the viscosity reached after the rotor rotates for a given time interval (Mooney time setting). JIS K 6300 specifies measuring the Mooney viscosity four minutes after the preheating time ends. However, SMV-301/301RT models allow the user to specify up to ten Mooney viscosity detection times.This part of ISO 289 specifies a method using a shearing-disc viscometer for measuring the Mooney viscosity of uncompounded or compounded rubbers. 2 Normative references. The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition .

mooney viscosity rpa

Time series prediction involves static and dynamic features. Extraneous input information hampers model performance, and the statistical attributes of time series change over time, affecting distribution. Targeted processing of input data for feature and distribution dynamics is vital. This article introduces AdaDynaTrans, an attention-based optimization model. It . The influence of mixed rubber processing technology on Mooney viscosity and burning time was studied. The results showed that the Mooney viscosity of mixed rubber increased with the extension of .This correlation makes it possible to predict the Mooney viscosity from GPC data with a precision of about 15% (± one standard deviation), independent of the molecular weight distribution of the polymer. The obtained correlation was much better than with either weight-average molecular weight or viscosity-average molecular weight with α = 0.67.(2) the rubber Mooney viscosity (shown in Table 6) and burning time (shown in table 7) were sampled and tested under the thin pass condition of roll temperature 90±5℃ and roll spacing 0.5mm .

Mooney Scorch ASTM D1646, small rotor at 121 °C (250 °F) Mooney Viscosity ASTM D1646, ten pass at 121 °C (250 °F) ODR (oscillating disk rheometer) ASTM D2084 Property Change After Heat Aging ASTM D573 Stress/Strain Properties 100% Modulus Tensile Strength (T-B) Elongation (E-B) ASTM D412, pulled at 8.5 mm/sec (20 in/min)5. The maximum test time: Mooney: 10min; Scorch: 120min (modification time during testing) 6. Mooney value of measuring range: 0 to 200 7. Mooney value resolution: 0.1 Mooney value 8. Mooney value measurement accuracy: ± 0.5 Mooney value 9. Calibrate accuracy: 100±0.5 Mooney value 10. Rotor speed: 2 ± 0.02r/min 11.

tk 100g moisture meter

tk100 multfunctional moisture meter hay moisture meter

Hay 1280 niñeras y canguros en Sitly en Pamplona. Acceso i.

Mooney viscosity—PC type distribute|mooney mdr viscosity